Pourquoi les fours de décarbonisation continue remplacent les décapants chimiques

Oct 18, 2022

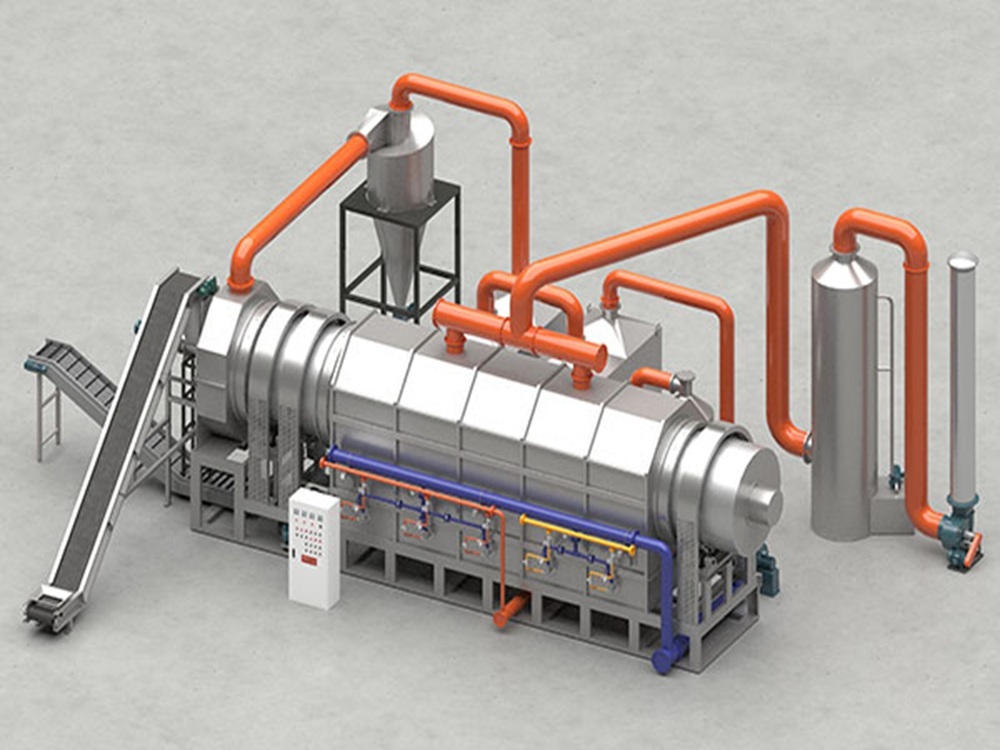

Dans le recyclage et la remise en état des métaux, le décapage des peintures et revêtements est une étape cruciale. Pendant des décennies, les décapants chimiques ont été la solution privilégiée. Aujourd'hui, cependant, les fours de décapage en continu s'imposent rapidement comme la solution de choix, offrant un excellent compromis entre efficacité, sécurité et durabilité. Alors, qu'est-ce qui rend cette technologie tellement supérieure ? Voici un aperçu simple de ses principaux avantages par rapport aux méthodes chimiques traditionnelles. 1. Efficacité inégalée et fonctionnement continu Imaginez une chaîne de montage pour le nettoyage des métaux. C'est essentiellement ce qu'est une chaîne de montage pour le nettoyage des métaux. four de décapage continu Contrairement aux procédés par lots, il fonctionne en continu, acheminant les pièces métalliques à travers différentes zones pour le chauffage, le traitement et le refroidissement. Ce flux de travail continu permet d'obtenir un rendement nettement supérieur. Que les pièces présentent des couches de peinture fines ou épaisses, les paramètres du four (température et vitesse de traitement, par exemple) s'ajustent facilement pour un décapage parfait et net. Cette flexibilité en fait la solution idéale pour le traitement efficace d'une grande variété de pièces métalliques, permettant ainsi des économies de temps et de main-d'œuvre considérables. 2. Une victoire incontestable pour la sécurité et l'environnement C’est peut-être là son principal avantage. Les décapants chimiques contiennent souvent des substances toxiques et agressives qui présentent des risques pour la santé des travailleurs et l’environnement. Leur manipulation en toute sécurité exige des mesures de protection strictes, et l’élimination des produits chimiques usagés génère des déchets dangereux. Le four de décapage élimine complètement ce problème. Il utilise des températures élevées dans un environnement contrôlé et sans oxygène pour décomposer la peinture en gaz et en une petite quantité de résidus solides. C'est un procédé purement physique : aucun produit chimique toxique n'est nécessaire. Cela signifie aucune émanation dangereuse pour les travailleurs, aucun risque de déversement de produits chimiques et aucune eau usée toxique à traiter. C'est une solution beaucoup plus propre et plus sûre pour tous. 3. Fonctionnement simple et entretien facile La gestion des décapants chimiques est complexe. Elle exige une surveillance rigoureuse, ainsi que des procédures de stockage et de manipulation précises afin de prévenir tout accident. À l'inverse, les fours de décapage en continu sont conçus pour la simplicité. Les unités modernes sont équipées de systèmes de contrôle automatisés qui gèrent l'ensemble du processus : la température, la vitesse du convoyeur et l'atmosphère sont contrôlées avec précision depuis un panneau de commande. Cette automatisation réduit les risques d'erreur humaine et minimise le besoin d'intervention d'opérateurs spécialisés. La maintenance est également simple et se limite généralement à des inspections régulières et à un entretien de base, garantissant ainsi un fonctionnement fiable et durable. 4Peut manipuler presque toutes les pièces métalliques. La polyvalence est un atout majeur. Ces fours peuvent être adaptés au traitement de pièces métalliques de formes et de dimensions variées, des petits composants aux grandes pièces de structure. Grâce à un réglage précis des équipements, différents matériaux et types de revêtements peuvent être traités efficacement. Cette grande adaptabilité rend cette technologie utile dans de nombreux secteurs, notamment l'automobile, l'aérospatiale, le recyclage des métaux et la métallurgie en général. 5. Économe en énergie et rentable Bien que le chauffage d'un four nécessite de l'énergie, les modèles modernes à fonctionnement continu sont conçus pour une efficacité optimale. Des systèmes d'isolation et de récupération de chaleur performants captent et réutilisent la chaleur à l'intérieur du four, réduisant ainsi considérablement la consommation d'énergie. De plus, les gaz combustibles produits lors du décapage de la peinture peuvent souvent être récupérés et utilisés comme combustible, créant ainsi un cercle vertueux d'économie d'énergie. À terme, ces gains d'efficacité permettent de réduire les coûts d'exploitation par rapport aux dépenses récurrentes liées à l'achat et à l'élimination des décapants chimiques. Le passage des décapants chimiques à fours de décapage continu Ces fours représentent une avancée majeure pour l'industrie. Grâce à leur efficacité supérieure, leur sécurité renforcée, leurs avantages environnementaux et leur simplicité d'utilisation, ils ne constituent pas une simple alternative, mais une véritable amélioration. Ils s'inscrivent parfaitement dans les objectifs d'une production moderne et durable, permettant aux entreprises de travailler de manière plus intelligente, plus sûre et plus respectueuse de l'environnement.

EN SAVOIR PLUS