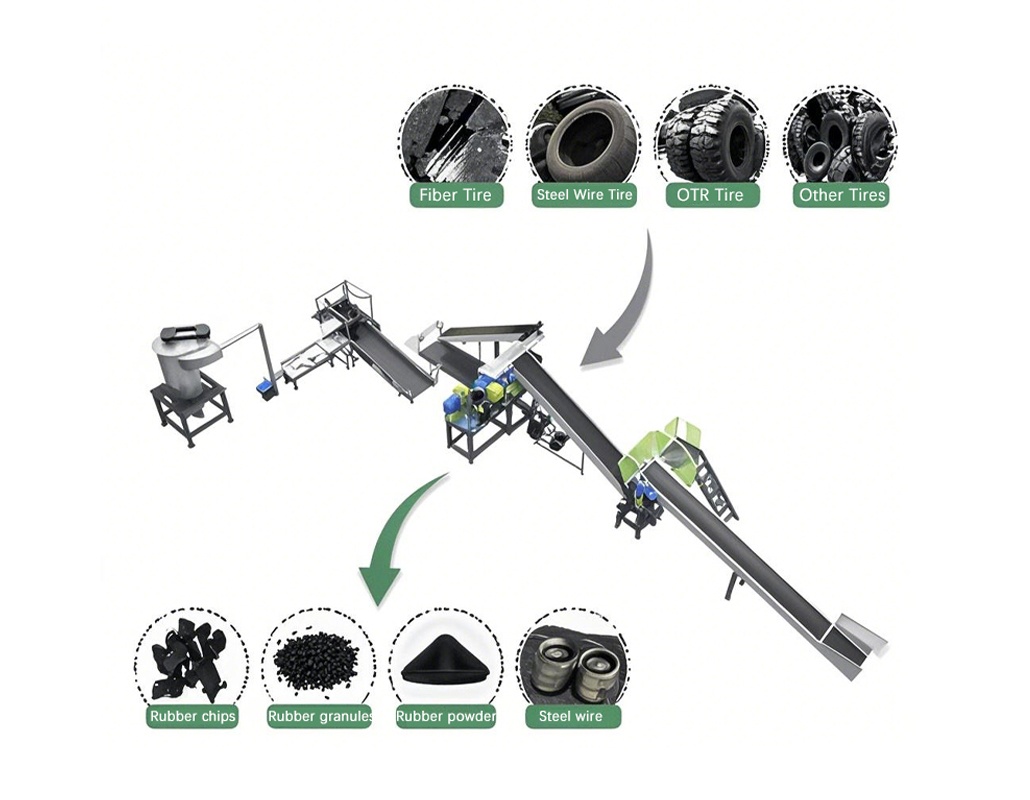

Waste tire processing equipment can completely separate and recycle rubber, steel wire and fiber in waste tires, and is suitable for rubber product recycling, tire steel wire recycling and other fields. The system is equipped with dust removal, water cooling and other devices, and uses PLC control to achieve automatic operation, with low energy consumption and pollution-free characteristics. The entire line occupies a small area and has low maintenance costs.

Working Process:

We have two types of wire pullers: single puller and double puller. They are used to completely pull out the inner tube wire of the tire at one time, so that the tire can be easily flattened or cut off later.

Features:

1. The equipment incorporates an integrated base plate, delivering industry-leading efficiency in wire extraction.

2. Its mechanical transmission system utilizes a rotary disc configuration for pull hooks, significantly reducing floor space requirements.

3. Standard protections include automated circuit interruption and OSHA-compliant safety cages.

The tire shredder efficiently processes steel-belted radial tires into 50×50mm rubber blocks while accommodating steel-reinforced waste construction.

Features:

Its cutter components are made of heat-treated chrome-vanadium alloy (HRC 58-62), which has excellent wear resistance and service life. It solves the problems of easy wear and degradation of blades, difficult replacement of complex components and expensive maintenance downtime. Compared with traditional crushing systems, it greatly reduces the labor intensity of operators.

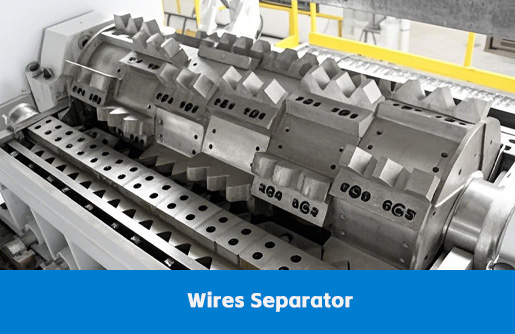

The wire separator processes tire-derived rubber blocks into granules ranging from 10-15mm.

Features:

1. Good separation effect: It can efficiently separate the steel wire and rubber in waste tires, and the separation rate can be as high as about 99%.

2. Large processing capacity: It can operate continuously and stably, with a large processing volume, and can meet the needs of large-scale waste tire processing.

3. Convenient tool replacement: The tools can be disassembled and installed independently, and can be disassembled quickly in a short time, which improves production continuity.

Français

Français English

English Русский

Русский Español

Español Português

Português عربي

عربي 日语

日语